A pioneering enterprise setting up India’s fully integrated solar module manufacturing line, revolutionizing the renewable energy sector.

About

Landsmill Group

Landsmill Group, a long-established conglomerate with a robust presence in the FMCG sector, under the leadership of the Promoters is venturing into a green and sustainable manufacturing sector in Solar through Landsmill Solar.

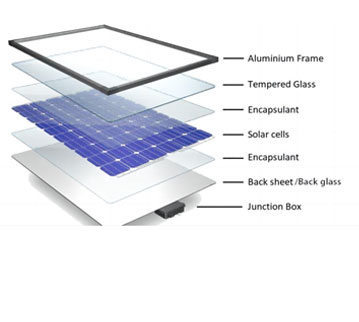

The Landsmill Group is establishing a groundbreaking venture in India’s renewable energy sector by setting up the country’s first fully integrated solar module manufacturing line. This pioneering project will encompass the entire production process, from raw materials to finished solar modules, including…

Landsmill Solar is committed to the above national resolve of achieving net-zero carbon status by 2035. The upcoming 5 Gigawatt Solar Module Manufacturing Preposition along with all accessories such as Glass, Encapsulant Vinyl Acetate (EVA), Solar Aluminum Frame, Solar PV Busbar Ribbon at Madhya Pradesh. The company is committed to the Green Energy Transformation Revolution of our great Nation.

Through our proposed investment of INR 1400 Crores, we shall be building a scalable and Sustainable green energy ecosystem of the nation.Company aims to build one of the world’s most technologically advanced Solar Energy Businesses which shall bridge the green energy divide in India and globally…

Climate change is a global emergency that goes beyond national borders. It is an issue that requires international cooperation and coordinated solutions at all levels. UN Climate Change (COP21) mandates substantial reduction in global greenhouse gas emissions to hold global temperature increase to well below 2°C above pre-industrial levels and pursue efforts to limit it to 1.5°C above pre-industrial levels,.

India has demonstrated its commitment to the COP26 by formally amending its Nationally Determined Contribution (NDC) to lower the emissions intensity of its GDP by 45% by 2030 compared to 2005 levels. To achieve its commitments India has set in motion an ambitious target of 500 GW of Renewal Energy capacity by 2030…

Our Latest Projects

Landsmill Renewables Private Limited

Landsmill Renewables Private Limited

What we shall do

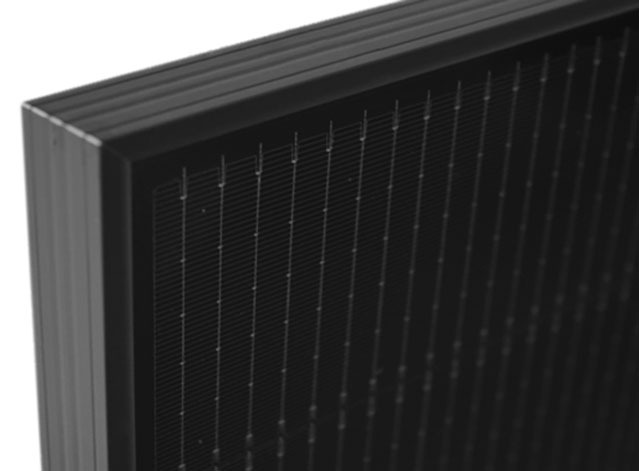

Landsmill Renewables Private Limited shall be establishing the 5GW Integrated Solar Module Assembly Line for TOPCon Technology. This world-class facility represents a monumental leap in innovation, sustainability, and energy independence, marking a new era for India’s clean energy capabilities.

Why N-Type Bifacial TOPCon Module?

- Highest Capacity in India: Capacity to supply 5GW per annum, i.e. one of the largest capacities in India.

- Higher Energy Conversion Efficiency: 25% module efficiency, maximizing solar energy output.

- Longer Lifespan: Advanced passivation layers enhance durability and minimize degradation.

- Superior Temperature Coefficients: Optimal performance even in extreme climates.

- Lower Levelized Cost of Energy (LCOE): More energy output with reduced long-term costs.

Capabilities

- First-of-its-Kind Integrated Facility:Our integrated assembly line consolidates every stage of manufacturing under one roof.

- Advanced Manufacturing Excellence:Employs state-of-the-art automation and innovative production techniques.

- Commitment to Local Manufacturing:Aligned with the Make in India initiative, our plant reduces dependency on imported solar modules.

Features

590 WP High

Efficiency Panels

5GW Annual

Output

Quality

Assurance

Larger Order

Capacity

Expert Team

Support

Landsmill Green Industries Private Limited (LGIPL)

Landsmill Green Industries Private Limited (LGIPL)

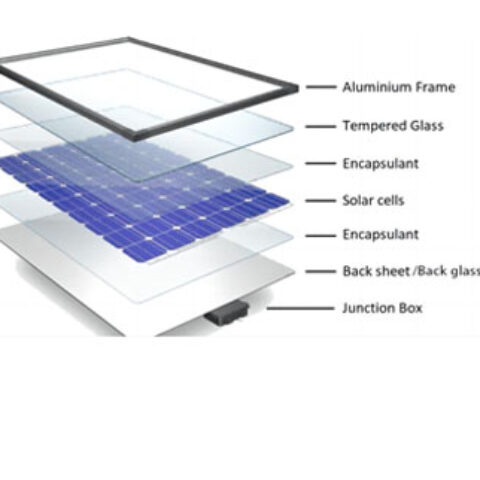

Landsmill Green Industries Private Limited (LGIPL) shall be providing a Pioneering Renewable Energy Solutions through manufacturing of Solar Glass for the PV module.

Solar glass plays a critical role in the photovoltaic (PV) industry, serving as a protective and functional layer for solar panels. The manufacturing process of solar glass combines precision engineering and advanced technologies to deliver high-performance products designed for durability and efficiency.

Key Features of Solar Glass Manufacturing:

- High-Transparency Glass Production

- Utilizes low-iron glass for superior light transmission, maximizing energy conversion efficiency.

- Tempering and Strengthening

- Glass undergoes thermal tempering to enhance durability, making it resistant to impacts and environmental stresses.

- Anti-Reflective Coating: An advanced coating reduces reflection and increases light absorption, optimizing solar panel performance

Solar glass is the backbone of solar energy systems, ensuring panels perform efficiently in diverse environments. With innovations in design and manufacturing, solar glass continues to drive the evolution of renewable energy.

Sustainability in Focus

Landsmill Green Industries Private Limited (LGIPL) shall be focusing on modern solar glass manufacturing which incorporates eco-friendly practices such as recycling raw materials and utilizing energy-efficient processes, aligning with the global push for sustainability. The glass line shall support the 5 GW solar module line and will help India become self reliant in the manufacturing of glass for solar PV.

The plant shall also produce the auxillary items being used in the manufacturing of PV modules:

A. Solar EVA Sheet

Solar EVA Sheet Manufacturing: Enhancing Solar Panel Performance

Landsmill Green Industries Private Limited (LGIPL) shall produce EVA (Ethylene Vinyl Acetate) sheets which are a critical encapsulation material in solar panel manufacturing, ensuring the longevity and efficiency of photovoltaic modules. The production of solar EVA sheets involves advanced material science and precision processes to meet stringent industry standards.

Key Features of Solar EVA Sheet Manufacturing:

- High Transparency and Adhesion

- EVA sheets are engineered to offer excellent optical transparency and strong adhesion to glass and backsheet layers, enhancing energy conversion efficiency.

- Durability and Weather Resistance

- Designed to withstand UV radiation, temperature fluctuations, and moisture, EVA sheets protect solar cells in various environmental conditions.

- Thermal Stability

- Manufactured with precise formulations to provide thermal stability, ensuring consistent performance over the panel’s lifespan.

- Customizable Formulations

- Tailored to meet specific requirements, such as low-shrinkage or anti-PID (Potential Induced Degradation) properties.

Sustainability and Innovation

Modern EVA sheet manufacturing integrates eco-friendly practices and innovative material developments to reduce environmental impact while improving performance.

Solar EVA sheets play an essential role in ensuring the durability and efficiency of solar panels, contributing to the advancement of renewable energy solutions worldwide

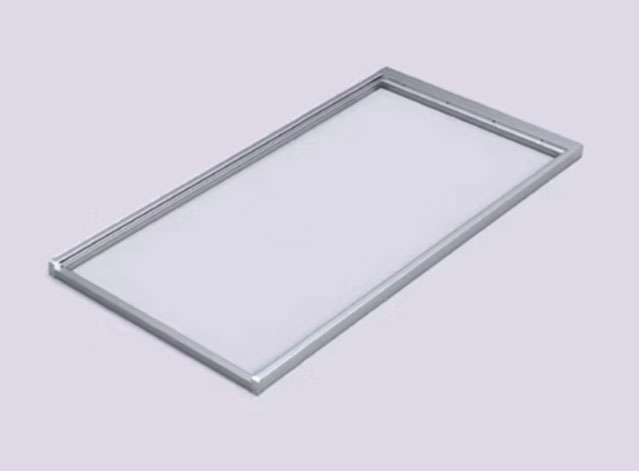

B. Solar Aluminium Frame

Landsmill Green Industries Private Limited (LGIPL) shall be manufacturing Solar Aluminium for Strength and Precision for Solar Panels

The aluminum frame is a vital component of solar panels, providing structural integrity and protection while ensuring ease of installation. The manufacturing process of solar aluminum frames combines advanced technology and precision engineering to meet the rigorous demands of the renewable energy industry.

Key Features of Solar Aluminum Frame Manufacturing:

- Lightweight and Durable Design

- High-quality aluminum alloys are used to produce frames that are lightweight yet robust, ensuring long-term reliability.

- Corrosion Resistance

- Frames are anodized or powder-coated for excellent resistance to corrosion, making them ideal for diverse environmental conditions.

- Customizable Solutions

- Frames are manufactured in various shapes and dimensions to accommodate different solar panel sizes and mounting systems.

- Precision Engineering

- Advanced extrusion and machining techniques ensure accurate dimensions and consistent quality.

Sustainability and Efficiency

Landsmill Green Industries Private Limited (LGIPL) shall be using modern manufacturing processes focus on sustainability, utilizing recyclable materials and energy-efficient production methods to reduce the environmental footprint. Solar aluminium frames are indispensable in ensuring the durability and efficiency of solar panels, supporting the industry’s growth towards a sustainable future.

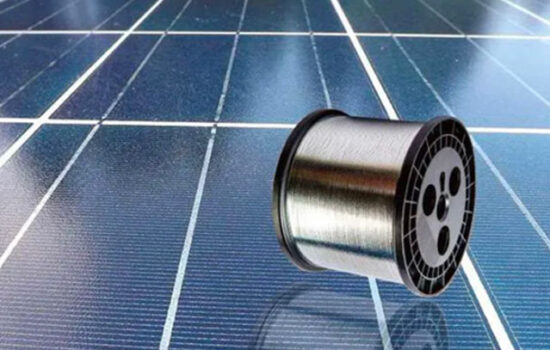

C. Solar PV Bush Bar Ribbon

Solar PV Busbar Ribbon Manufacturing: Enabling Efficient Energy Flow

Landsmill Green Industries Private Limited (LGIPL)’s Solar PV busbar ribbons are essential components in photovoltaic panels, facilitating the efficient transfer of electrical current between solar cells. The manufacturing of these ribbons combines precision engineering and advanced metallurgical processes to meet the high-performance requirements of modern solar technologies.

Key Features of Solar PV Busbar Ribbon Manufacturing:

- High Conductivity Materials

- Manufactured using high-purity copper or aluminum, coated with a thin layer of solder to ensure excellent electrical conductivity and ease of soldering.

- Precision Engineering

- Advanced rolling and extrusion techniques ensure consistent thickness, width, and flatness, optimizing performance and compatibility with automated solar panel assembly lines.

- Surface Coating for Durability

- Special coatings enhance corrosion resistance and improve adhesion, ensuring long-term reliability in various environmental conditions.

- Customizable Specifications

- Produced in a range of sizes, shapes, and surface finishes to suit different solar cell designs, including multi-busbar and half-cut cell configurations.

Sustainability and Efficiency

Modern manufacturing processes focus on material efficiency and recycling, reducing waste while delivering high-quality products for renewable energy systems.

Solar PV busbar ribbons are critical in maximizing the efficiency and reliability of photovoltaic modules, playing a pivotal role in advancing solar energy technology.

Landsmill Green Energy Private Limited

Landsmill Green Energy Private Limited

Landsmill Green Energy Private Limited shall be in the business of core photovoltaic cell technology with TOPCon architecture, known for high efficiency and bifacial design, allowing energy capture from both sides. Company shall be preparing cell which shall features a 182mm x 182mm dimension, 16 busbars (BB), and an efficiency of 26%, indicating top-tier

Topcon Solar Cells: The Future of Solar Energy

At the cutting edge of solar technology, Topcon (Tunnel Oxide Passivated Contact) solar cells represent a revolutionary advancement in photovoltaic efficiency and performance. Designed to overcome the limitations of traditional solar cells, Topcon cells are setting new benchmarks in the solar industry.

What Are Topcon Solar Cells?

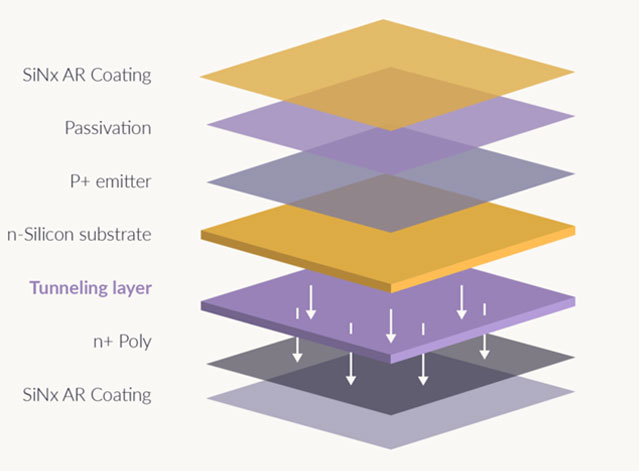

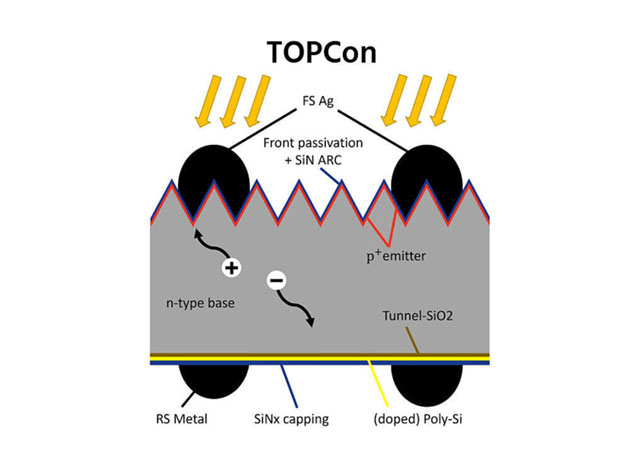

Topcon solar cells are next-generation photovoltaic cells that use an innovative Tunnel Oxide Passivated Contact structure. This technology enhances energy conversion efficiency by minimizing electron recombination and improving charge carrier collection.

The key to their performance lies in the ultra-thin tunnel oxide layer, combined with a doped polysilicon layer, which ensures maximum energy capture and long-term durability.

Why Choose Topcon Technology?

- Unparalleled Efficiency

- Topcon cells consistently achieve efficiency levels above 23%, outperforming conventional technologies like PERC (Passivated Emitter and Rear Cell).

- Enhanced Temperature Performance

- With a superior temperature coefficient, Topcon cells deliver excellent performance even in high-temperature environments, ensuring higher energy yields year-round.

- Durability & Longevity

- Advanced passivation techniques make Topcon cells resistant to degradation, providing reliable performance for decades.

- Sustainability

- Increased efficiency reduces the number of panels needed for installations, optimizing space utilization and minimizing the carbon footprint.

The Future of Solar Energy

As the world shifts toward renewable energy, Topcon solar cells are paving the way for more efficient, cost-effective, and sustainable solar solutions. Their ability to generate more power in less space makes them a game-changer for high-performance solar systems.

TOPCon Cell Technology

- Continuous technological advancements in solar cell technology have improved the efficiency and cost-effectiveness of solar energy over the years. (Tunnel Oxide Passivated Contact) cell is technologically more advanced than the prevalent PERC cell technology offering better power generation efficiency.

- TOPCon cells are generally a type of n-type solar cell. N-type cells are made with a semiconductor material that has been doped with phosphorus, which gives the material a negative charge. This type of cell has several advantages over p-type cells, including higher efficiency and better performance in low-light conditions.

- TOPCon cell technology is a further development of PERC technology. In PERC cells, the rear surface of the solar cell is passivated with a thin layer of aluminium oxide (Al2O3). This layer helps to reduce recombination losses, which can improve the efficiency of the cell.

- In TOPCon cells, a thin layer of silicon dioxide (SiO2) is deposited on top of the Al2O3 layer. This layer creates a tunnelling junction, which allows electrons to flow more easily from the p-type emitter to the n-type substrate. This tunnelling junction helps improve the efficiency of the cell by reducing the series resistance.

Landsmill Green Energy Private Limited shall be producing cell for its 5 GW solar PV manufacturing lines as well as national and international PV market.

Board of Directors

Management Team

Resources & Blog

Media

What’s New